Why pallet wrapping machine repair is crucial to packaging reliability

Wiki Article

Typical Repair Issues With a Pallet Wrapping Equipment and How to Deal with Them

Pallet Wrapping makers are crucial in many industries for safeguarding products. Nevertheless, they frequently deal with usual repair work concerns that can interfere with operations. Inconsistent Film Tension, mechanical jams, malfunctioning sensing units, and electric troubles are simply a few difficulties drivers come across. Comprehending these issues and their options can boost device efficiency and reduce downtime. Yet, resolving these issues needs even more than simply basic knowledge; it requires a systematic approach. What techniques can ensure peak performance?Inconsistent Film Tension

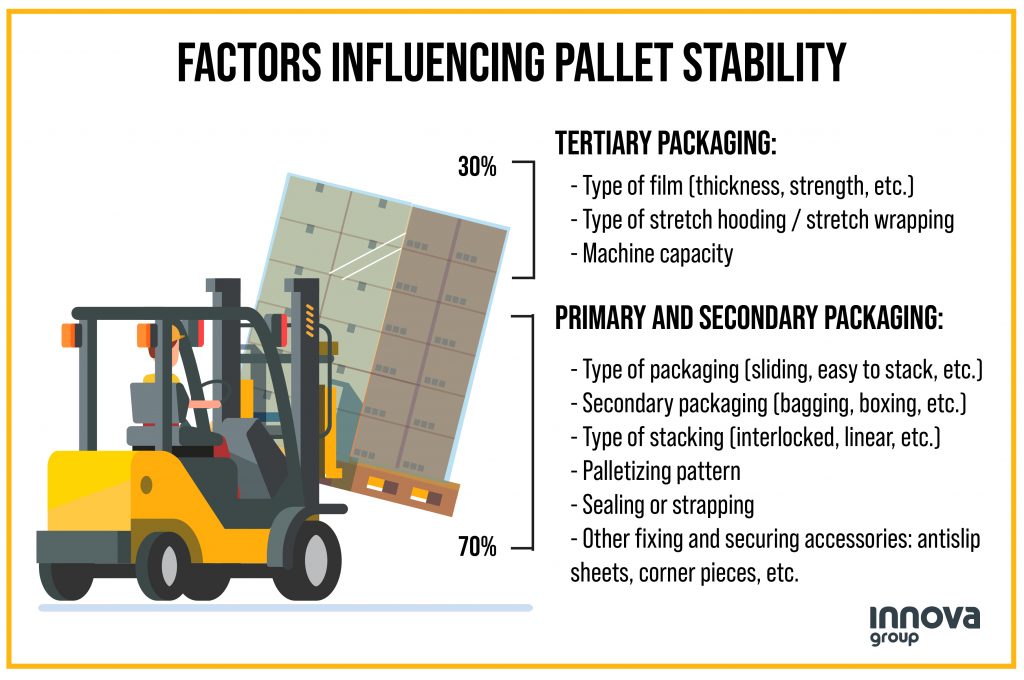

Inconsistent Film Tension can substantially impact the effectiveness of pallet Wrapping machines. When the Tension differs, it leads to uneven Wrapping, which can jeopardize tons stability and result in product damage during transport. Appropriate Film Tension is crucial for preserving the integrity of the wrapped tons, as it assures that the stretch Film sticks evenly around the pallets. Aspects adding to irregular Tension consist of incorrect Film setup, worn-out components, or incorrect machine setups. Because of this, normal maintenance and adjustments are vital in avoiding these concerns. Operators ought to be educated to keep track of the Film Tension continuously and make necessary adjustments to the machine setups as needed. Addressing these variances promptly can improve the overall performance and reliability of pallet Wrapping procedures.

Mechanical Jams and Blockages

Mechanical jams and obstructions can considerably disrupt the procedure of pallet Wrapping equipments, resulting in increased downtime and reduced efficiency. These problems often arise from incorrect loading of pallets, twisted Film, or damaged parts that fall short to operate smoothly. Regular maintenance, including the lubrication of relocating parts, can aid stop these issues. Operators must additionally verify that the Film is properly lined up and that there are no international items obstructing the equipment. Additionally, regular inspections for damage can identify potential troubles prior to they rise right into substantial malfunctions. By dealing with these mechanical problems immediately, facilities can keep smoother operations and minimize disturbances in the Wrapping procedure, eventually improving overall efficiency.Faulty Sensors and Controls

Film Breakage or Poor Attachment

Film breakage or poor attachment can considerably impede the effectiveness of pallet Wrapping operations. These concerns usually originate from improper Film Tension get redirected here setups or making use of incompatible Wrapping materials. When the Film is too loose, it might not stick appropriately to the load, leading to shifting or damage during transportation. Conversely, extreme Tension can cause Film breakage, creating hold-ups and extra product waste. Routine maintenance checks are important to ensure that the Wrapping machine's elements, such as rollers and Film dispensers, are working appropriately. Additionally, drivers must be trained to identify indications of Film high quality deterioration and adjust setups accordingly. Attending to these concerns properly can enhance efficiency and decrease operational costs related to film-related problems.Electrical Concerns and Power Failures

Reliability is essential in pallet Wrapping operations, as electrical problems and power failings can interfere with efficiency and cause substantial downtime. Usual electric issues include malfunctioning electrical wiring, blown fuses, and malfunctioning control panels. These concerns can commonly be mapped back to deterioration or incorrect maintenance. Routine inspections are vital to determine possible faults prior to they rise. Additionally, validating that the device is attached to a stable power source can mitigate power failure risks. In cases of failure, repairing steps consist of examining connections, changing merges, and resetting the control board. For persistent issues, speaking with a specialist service technician is suggested to assure security and bring back capability effectively. Aggressive treatment can greatly reduce the effect of electrical failures on operations.Frequently Asked Inquiries

Exactly how Commonly Should I Do Upkeep on My Pallet Wrapping Maker?

The frequency of maintenance for a pallet Wrapping machine commonly depends upon use. pallet wrapping machine repair. Normal examinations each month, along with comprehensive maintenance every 6 months, can aid ensure peak performance and durability of the informative post equipmentWhat Kind Of Film Functions Ideal for My Particular Wrapping Demands?

Figuring out the very best Film for details Wrapping requirements entails examining factors such as tons weight, item kind, and environmental conditions. Numerous Film types, including stretch, reduce, and hybrid, deal unique advantages tailored to various applications.Can I Use Recycled Film in My Pallet Wrapping Equipment?

Making use of recycled Film in pallet Wrapping equipments is usually possible, yet it may affect device efficiency and load safety. Users ought to guarantee compatibility and examination the Film to prevent prospective concerns during operation.Exactly How Can I Enhance the Efficiency of My Pallet Wrapping Refine?

To improve the effectiveness of the pallet Wrapping procedure, one should maximize maker setups, frequently maintain tools, train operators completely, and analyze process for potential bottlenecks, making certain seamless procedure and taking full advantage of productivity throughout the Wrapping cycle.What Security Preventative Measures Should I Take While Running the Device?

When running the device, it is vital to wear ideal personal protective tools, assure a clear work space, regularly evaluate safety functions, and maintain a secure range from moving parts to stop injuries and mishaps.

Irregular Film Tension can substantially affect the performance of pallet Wrapping equipments. pallet wrapping machine repair. Appropriate Film Tension is important for keeping the honesty of hop over to these guys the covered lots, as it ensures that the stretch Film sticks consistently around the pallets. Film damage or inadequate adhesion can significantly impede the efficiency of pallet Wrapping procedures. Routine upkeep checks are essential to assure that the Wrapping device's components, such as rollers and Film dispensers, are working properly. The use of recycled Film in pallet Wrapping devices is typically feasible, however it may impact maker performance and tons safety

Report this wiki page